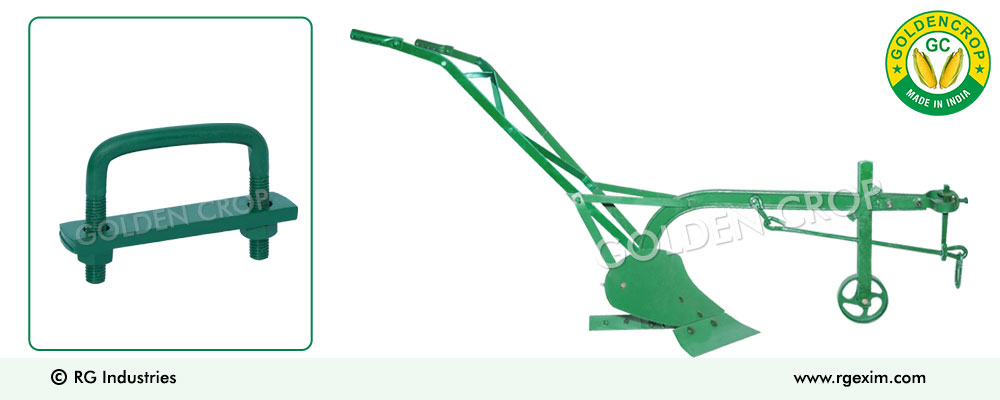

Plough D Clamp

A D-clamp in a plough is a type of clamp that is shaped like the letter “D”. The D-clamp is typically used to hold or secure parts of the plough body or framework in place, such as the handles or supports. The D-clamp is positioned at different points on the plough body and is attached to the plough using screws or bolts. The D-clamp is an important part of the plough as it helps to ensure that all parts of the plough are securely in place and working properly. Additionally, the D-clamp can also be used to adjust the position of parts of the plough to suit different types of soil and cultivation requirements. The D-clamp is an important part of the overall design and functionality of the plough and helps to ensure that it performs effectively and efficiently when used for cultivation.

Features of D Clamp

The features of D clamp in a plough include:

D-shape

The D clamp gets its name from its D-shaped design. It consists of a metal bracket or clamp that resembles the letter “D” when viewed from the side. This shape allows for secure attachment and prevents the ploughshare from slipping or detaching during use.

Attachment Point

The D clamp is positioned near the heel of the ploughshare, where it connects to the plough beam. It serves as the point of attachment, securing the ploughshare in place and providing a stable connection between the ploughshare and the plough beam.

Fastening Mechanism

The D clamp typically uses bolts or pins to fasten tightly around the plough beam. These fastening mechanisms are tightened to securely hold the ploughshare and ensure that it remains in place during the ploughing process.

Stability

One of the key features of the D clamp is to provide stability to the ploughshare. By firmly attaching the ploughshare to the plough beam, it helps maintain the proper alignment of the ploughshare, preventing it from shifting or wobbling during ploughing.

Strength and Durability

The D clamp is designed to withstand the forces and stresses encountered during ploughing. It is made of sturdy and durable materials, such as metal, to ensure that it can withstand the rigors of agricultural operations.

Easy Installation and Removal: The D clamp is designed for easy installation and removal, allowing for efficient assembly and disassembly of the ploughshare when necessary. This feature facilitates maintenance, repair, or replacement of the ploughshare or other components of the plough.

Size of D Clamp

The size of the D clamp in a plough can vary depending on factors such as the design of the plough, regional variations, and specific farming practices. There is no standardized or fixed size for the D clamp as it can be customized based on individual preferences and requirements.

Typically, the size of the D clamp is determined by its dimensions, including the width and thickness of the metal bracket or clamp. The width of the D clamp refers to the distance across the opening of the clamp, while the thickness refers to the measurement from the inner surface to the outer surface of the clamp.

The size of the D clamp is influenced by factors such as the size of the plough beam, the strength of the materials used, and the desired level of stability and strength required for the ploughshare attachment.

Use of D Clamp

A “D clamp” in the context of a plough is a component that is used to attach the ploughshare to the plough beam. It is named after its shape, which resembles the letter “D”.

The primary use of the D clamp in a plough is to secure the ploughshare firmly to the plough beam, ensuring a stable connection between the two. It is typically positioned near the heel of the ploughshare, where it attaches to the plough beam.

The D clamp consists of a metal bracket or clamp that encircles the plough beam and holds the ploughshare in place. It is fastened tightly with bolts or pins, preventing the ploughshare from coming loose or detaching during the ploughing process.

The D clamp plays a crucial role in maintaining the alignment and stability of the ploughshare. It helps transfer the pulling force from the oxen to the ploughshare, ensuring that the plough cuts into the soil evenly and maintains a consistent depth.